Precision Optics Manufacturing

OTéO know-how extands on lapping, polishing and measurement of optics.

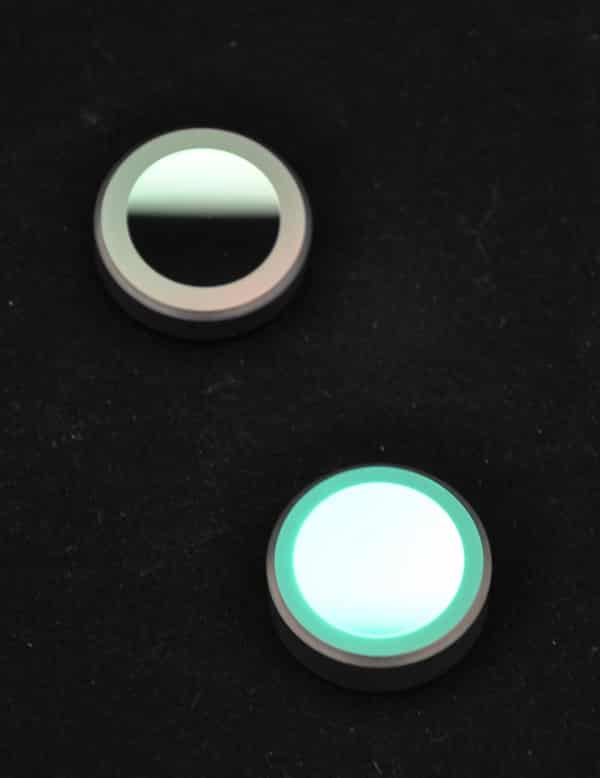

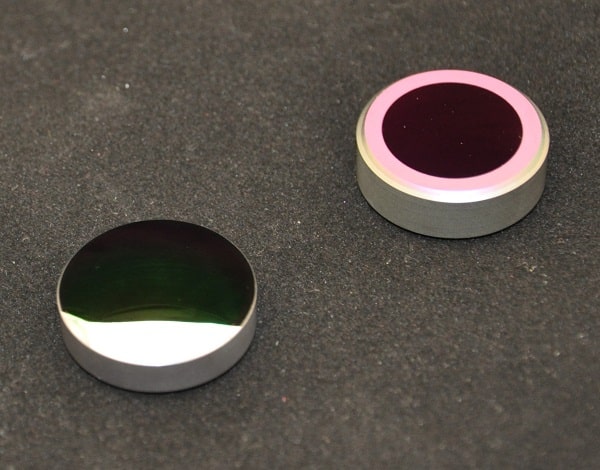

Coatings are manufactured through professional partnership following your specifications.

We manufacture from prototype to volume.

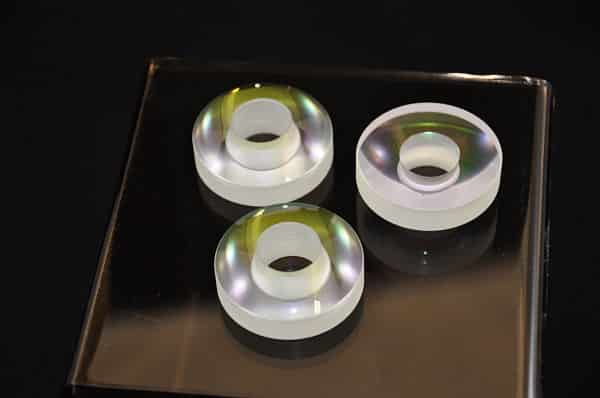

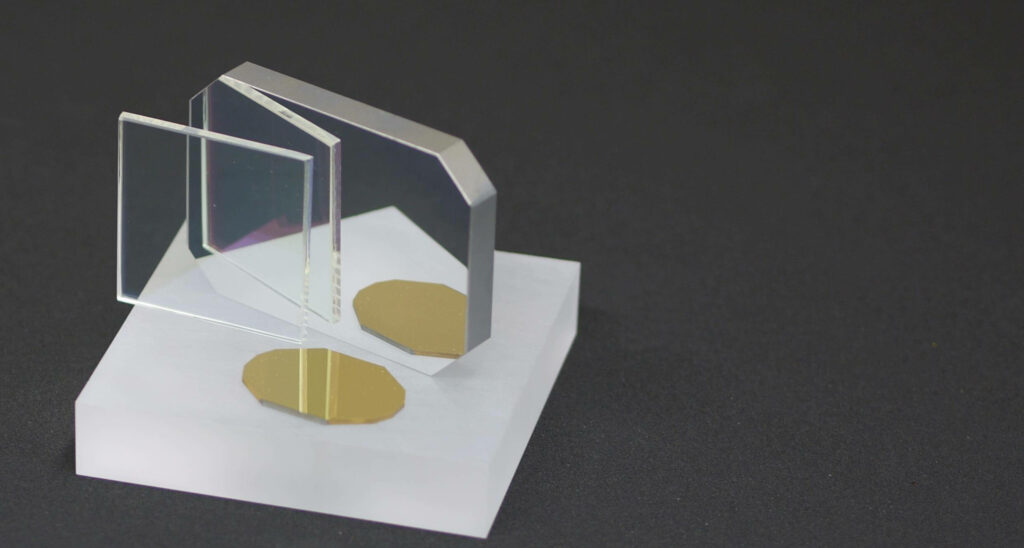

Manufacturing assemblies are done using glue, wax or molecular adherence, depends on your product.

Our experienced optics know-how allows us to answer to your optics projects.

Adhérence Moléculaire, en Optique de Précision , OTéO Optics

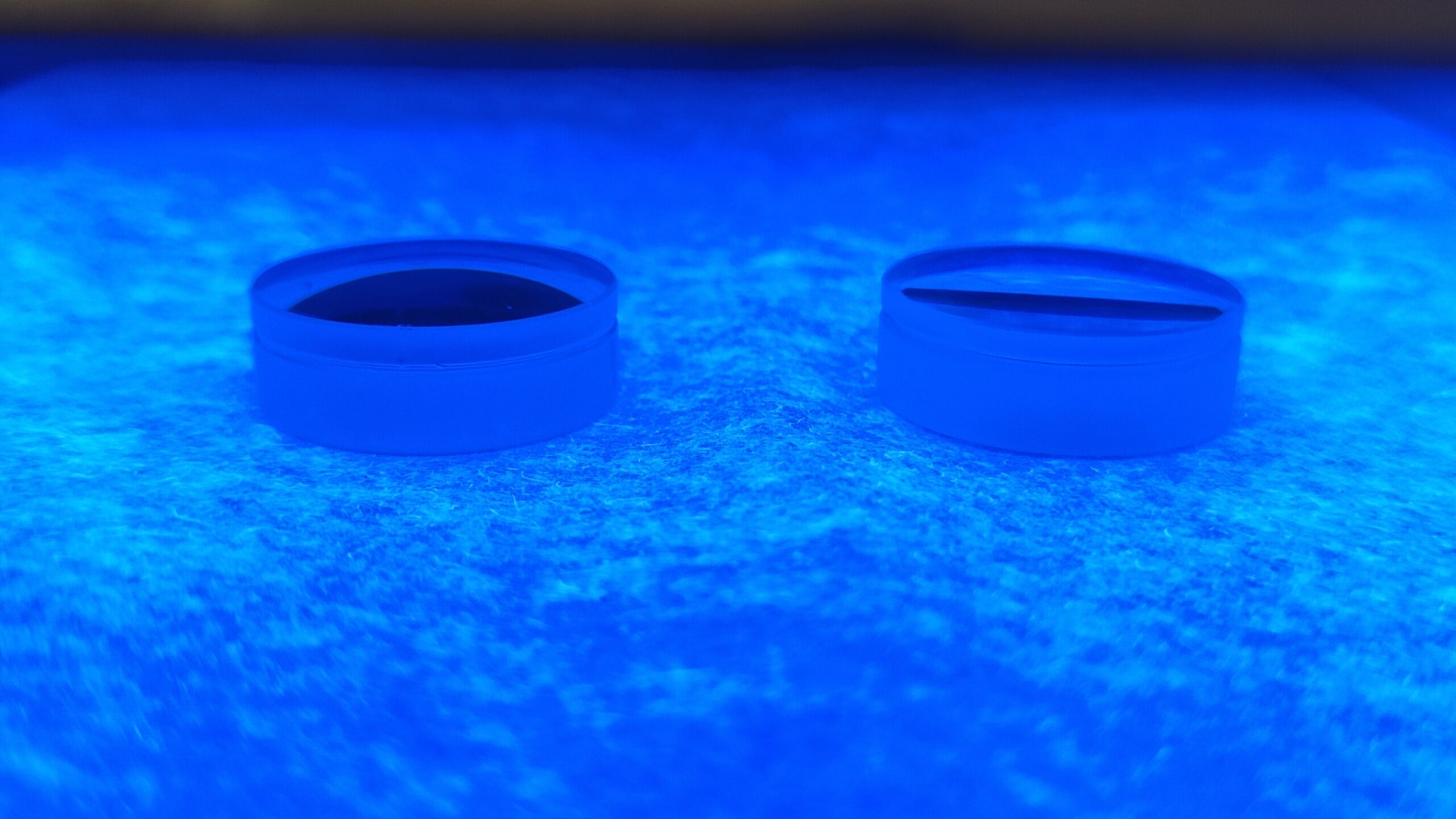

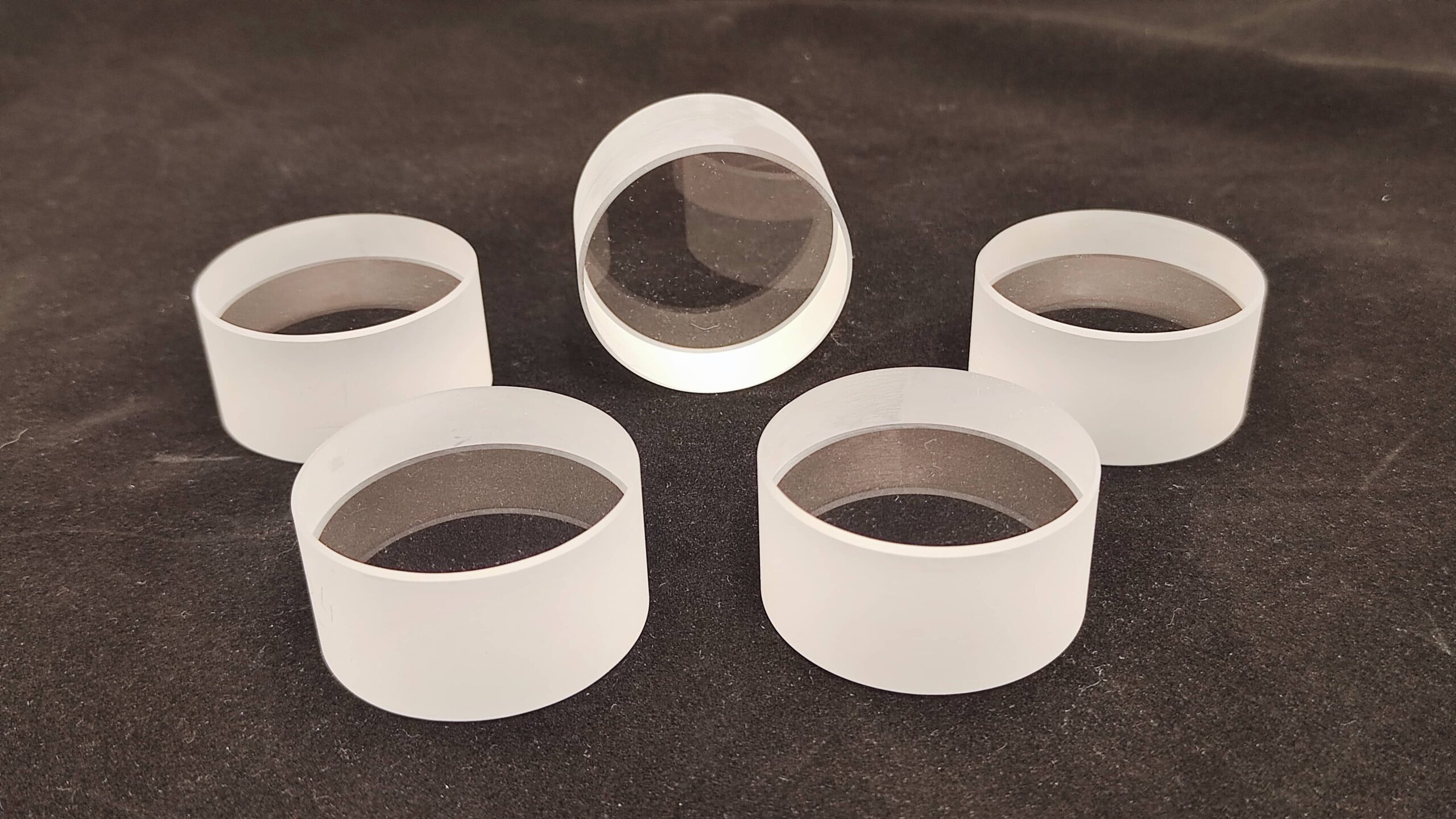

Optics polishing

We polish your optics following your needs !

Capabilities :

- Dimensions : 1 mm – 600 mm (Epaisseur : 70 μm – 500 mm)

- Flatness : λ / 20 ( Ø 100 mm). λ/10 (Ø 250mm)

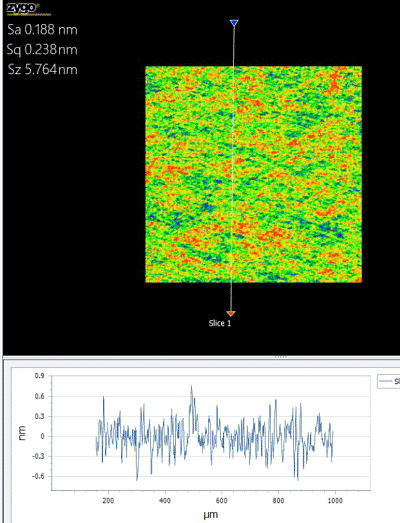

- Roughness : < 0.5nmRMS (< 0.25nmRMS function of material )

- Angle tolerances : < 0.5 arc-second

- Parallelism : < 0.1 arc-second

- Scratch-Dig : 60-40 standard, down to 20-10 according to dimensions

- Control PV : Zygo Gpi

Specific geometry :

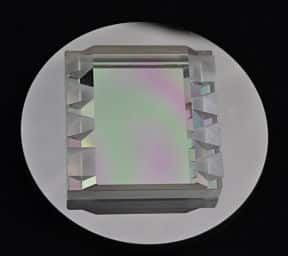

We polish planes or complex surfaces, aspherics, torus, groove presence, weight reduction shapes

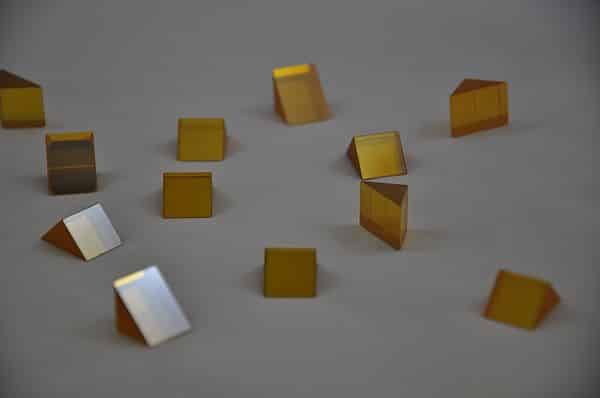

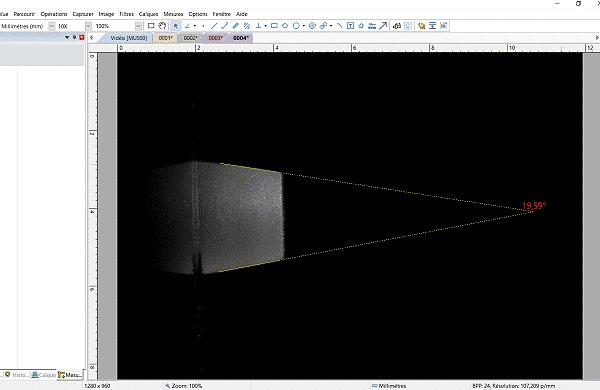

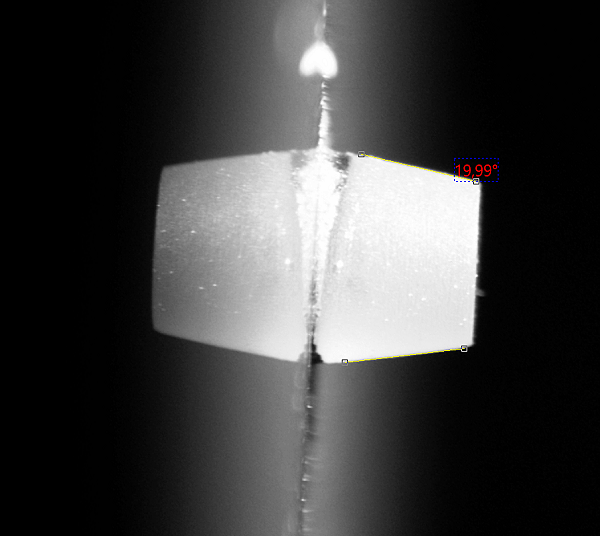

Angles prisms accuracy inferior to arc-second !

Coating partners : Optimask, Umicore

All substrates

Our opticians have a large experience polishing all substrates used in optics.

- Glasses : SiO2 (C79-80, silica HERAEUS, Suprasil, infrasil…)

- Metals : Steel, Aluminium, Copper, Titanium, tin, Stainless Steel, CUW,…

- Cristals : Fluorin, CAF2, BaF2, LiF, MgF2, Quartz, KDP…

- IR : Ge, Si, ZnSe, ZnS, CaF2…

- Ceramics : SiC and compounds

- Plastics : PMMA, PC, Lexan…

- Vitroceramics : ZeroDur

Control

- Zygo GPi

- Curvature Radius measurement : (+/-2µm for Rc<1m)

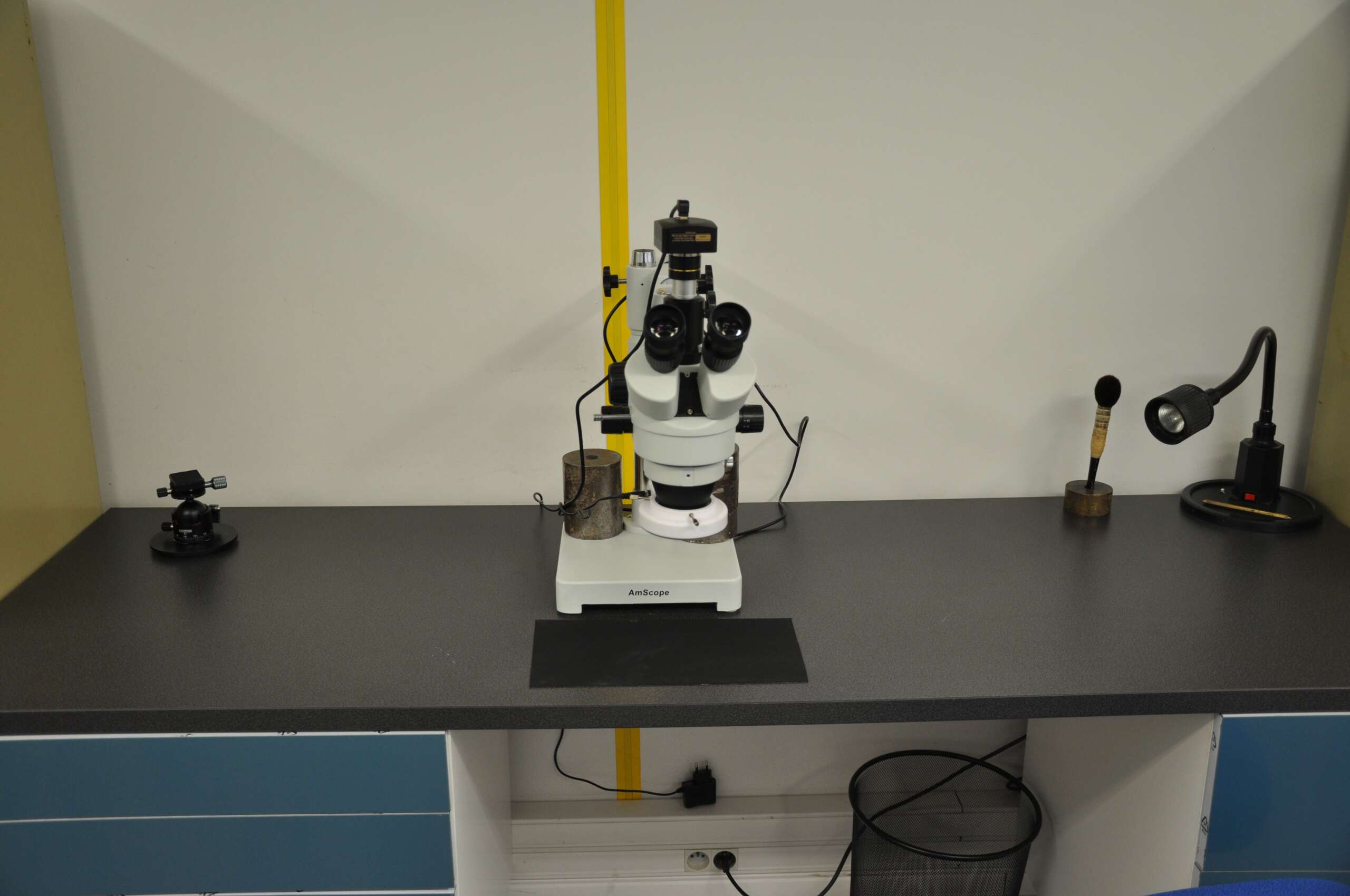

- Bino + measuring camera

- Interferometric Goniometer < 0.1 arc-seconde

Gallery